Market Policies for Chip Resistors

I. Introduction

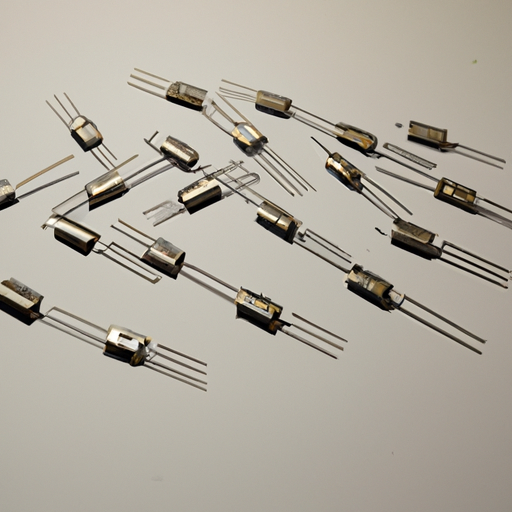

Chip resistors, small electronic components that resist the flow of electric current, play a crucial role in modern electronic devices. They are integral to the functioning of various applications, from consumer electronics to automotive systems. As the demand for electronic devices continues to rise, understanding the market policies that govern chip resistors becomes essential for manufacturers, suppliers, and consumers alike. This blog post explores the market policies affecting chip resistors, providing insights into the regulatory framework, pricing strategies, supply chain management, and future outlook.

II. Market Overview

A. Global Demand for Chip Resistors

The global demand for chip resistors has surged in recent years, driven by the rapid growth of the electronics industry. As technology advances, the miniaturization of electronic components has become a significant trend, leading to an increased need for compact and efficient chip resistors. These components are widely used across various sectors, including automotive, consumer electronics, telecommunications, and industrial applications. The rise of smart devices and automation further fuels this demand, as these technologies require reliable and precise electronic components.

B. Key Players in the Chip Resistor Market

The chip resistor market is characterized by several key players, including major manufacturers such as Yageo Corporation, Vishay Intertechnology, and Panasonic. These companies dominate the market, holding significant shares due to their established reputations, extensive product lines, and global distribution networks. Market share analysis reveals a competitive landscape, with ongoing innovations and product developments driving competition among manufacturers.

C. Trends Influencing the Market

Several trends are shaping the chip resistor market. The miniaturization of electronic components is a primary driver, as manufacturers seek to create smaller, more efficient devices. Additionally, the shift towards automation and smart devices is influencing the design and functionality of chip resistors, necessitating advancements in technology and materials.

III. Regulatory Framework

A. International Standards and Certifications

The chip resistor market is subject to various international standards and certifications that ensure product quality and safety. ISO standards play a vital role in establishing quality management systems, while RoHS (Restriction of Hazardous Substances) compliance ensures that products are free from harmful materials. Additionally, REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations govern the use of chemicals in manufacturing, further emphasizing the importance of compliance in the industry.

B. Regional Regulations

Regulatory frameworks vary across regions, impacting the manufacturing and distribution of chip resistors. In North America, stringent regulations govern electronic components, focusing on safety and environmental impact. Europe has similar regulations, with an emphasis on sustainability and consumer protection. In the Asia-Pacific region, regulations are evolving, with countries like China implementing stricter standards to enhance product quality and safety.

C. Impact of Regulations on Manufacturing and Distribution

Compliance with these regulations can significantly impact manufacturing processes and distribution strategies. Manufacturers must invest in quality control measures and ensure that their products meet the required standards. This can lead to increased production costs, which may be passed on to consumers. However, adherence to regulations also enhances product reliability and safety, ultimately benefiting the market.

IV. Pricing Policies

A. Factors Influencing Pricing of Chip Resistors

The pricing of chip resistors is influenced by several factors, including raw material costs, manufacturing processes, and supply chain dynamics. Fluctuations in the prices of materials such as copper and silicon can directly impact production costs. Additionally, advancements in manufacturing technology can lead to cost savings, which may be reflected in pricing strategies.

B. Pricing Strategies Employed by Manufacturers

Manufacturers employ various pricing strategies to remain competitive in the market. Cost-plus pricing involves calculating the total cost of production and adding a markup for profit. Competitive pricing focuses on setting prices based on competitors' rates, while value-based pricing considers the perceived value of the product to consumers. Each strategy has its advantages and challenges, and manufacturers must carefully assess market conditions to determine the most effective approach.

C. Impact of Tariffs and Trade Policies on Pricing

Tariffs and trade policies can also influence pricing in the chip resistor market. Changes in trade agreements or the imposition of tariffs on imported materials can lead to increased production costs, prompting manufacturers to adjust their pricing strategies. Understanding these dynamics is crucial for stakeholders in the industry.

V. Supply Chain Management

A. Overview of the Supply Chain for Chip Resistors

The supply chain for chip resistors involves several stages, from raw material sourcing to manufacturing and distribution. Manufacturers must secure reliable sources of raw materials, such as resistive films and substrates, to ensure consistent production. The manufacturing process involves precision engineering and quality control to produce high-performance chip resistors. Finally, distribution channels play a critical role in delivering products to customers efficiently.

B. Challenges in the Supply Chain

The chip resistor supply chain faces several challenges, including global disruptions caused by pandemics, geopolitical tensions, and natural disasters. These disruptions can lead to delays in production and distribution, impacting the availability of chip resistors in the market. Additionally, managing lead times and inventory levels is crucial for manufacturers to meet customer demand while minimizing excess stock.

C. Strategies for Effective Supply Chain Management

To navigate these challenges, manufacturers can adopt several strategies for effective supply chain management. Diversifying suppliers can reduce reliance on a single source and mitigate risks associated with disruptions. Just-in-time manufacturing can help optimize inventory levels, ensuring that products are available when needed without incurring excess costs. Furthermore, leveraging technology for supply chain optimization can enhance visibility and efficiency throughout the process.

VI. Market Entry Strategies

A. Approaches for New Entrants in the Chip Resistor Market

New entrants in the chip resistor market can explore various strategies to establish their presence. Joint ventures and partnerships with established manufacturers can provide access to resources and expertise. Mergers and acquisitions can also facilitate market entry by combining strengths and capabilities. Direct investment in manufacturing facilities can enable new players to produce chip resistors independently.

B. Barriers to Entry

However, several barriers to entry exist in the chip resistor market. High capital requirements for manufacturing facilities and equipment can deter potential entrants. Established competition poses a challenge, as existing players have established brand recognition and customer loyalty. Additionally, navigating regulatory hurdles can be complex and time-consuming for new entrants.

C. Opportunities for Innovation and Differentiation

Despite these challenges, opportunities for innovation and differentiation exist. New entrants can focus on developing unique products or technologies that address specific market needs. Emphasizing sustainability and eco-friendly practices can also resonate with consumers, providing a competitive edge in the market.

VII. Sustainability and Environmental Policies

A. Growing Emphasis on Sustainability in Electronics

Sustainability has become a significant focus in the electronics industry, with increasing pressure on manufacturers to adopt eco-friendly practices. Consumers are becoming more conscious of the environmental impact of their purchases, prompting manufacturers to prioritize sustainability in their operations.

B. Eco-Friendly Manufacturing Practices

Manufacturers of chip resistors are exploring eco-friendly manufacturing practices, such as reducing waste, minimizing energy consumption, and using sustainable materials. Implementing these practices not only benefits the environment but can also enhance brand reputation and attract environmentally conscious consumers.

C. Impact of Environmental Policies on Chip Resistor Production

Environmental policies can influence chip resistor production by imposing regulations on waste management, emissions, and resource usage. Compliance with these policies may require manufacturers to invest in cleaner technologies and processes, impacting production costs and pricing strategies.

VIII. Future Outlook

A. Predictions for the Chip Resistor Market

The future of the chip resistor market appears promising, with predictions of continued growth driven by technological advancements and evolving consumer preferences. As the demand for smaller, more efficient electronic devices increases, manufacturers will need to innovate and adapt to meet these changing needs.

B. Potential Challenges and Opportunities

While opportunities abound, potential challenges such as supply chain disruptions, regulatory changes, and intense competition may arise. Manufacturers must remain agile and responsive to navigate these challenges effectively.

C. Role of Market Policies in Shaping the Future of Chip Resistors

Market policies will play a crucial role in shaping the future of chip resistors. Regulatory frameworks, pricing strategies, and sustainability initiatives will influence manufacturing practices and market dynamics. Stakeholders must stay informed and engaged with these policies to ensure success in the evolving landscape.

IX. Conclusion

In conclusion, understanding the market policies for chip resistors is essential for stakeholders in the electronics industry. From regulatory frameworks to pricing strategies and supply chain management, various factors influence the market dynamics. As the demand for chip resistors continues to grow, manufacturers must navigate challenges and seize opportunities to thrive in this competitive landscape. By prioritizing sustainability and innovation, the chip resistor market can contribute to a more efficient and environmentally friendly electronics industry in the future.