What are the Product Standards for Resistors?

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. These passive components are essential for a wide range of applications, from simple circuits to complex electronic devices. However, the effectiveness and reliability of resistors depend significantly on adherence to established product standards. This blog post aims to explore the various product standards for resistors, their importance, and the implications for manufacturers and engineers in the electronics industry.

II. Understanding Resistors

A. Basic Principles of Resistors

Resistors are components that limit the flow of electric current in a circuit. They are characterized by their resistance value, which is measured in ohms (Ω). The primary function of a resistor is to create a voltage drop, thereby controlling the amount of current that can pass through a circuit. This is essential for protecting sensitive components, dividing voltages, and setting bias points in transistors.

1. Function and Role in Circuits

In any electronic circuit, resistors serve multiple purposes. They can be used to:

Limit Current: By restricting the flow of current, resistors protect components from damage due to excessive current.

Voltage Division: Resistors can be arranged in series or parallel configurations to create specific voltage levels required by different parts of a circuit.

Signal Conditioning: In analog circuits, resistors are used to filter signals, adjust gain, and stabilize circuits.

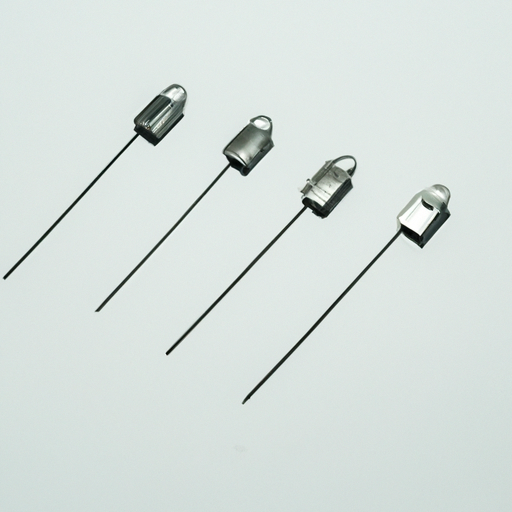

2. Types of Resistors

Resistors come in various types, each designed for specific applications:

Fixed Resistors: These resistors have a constant resistance value and are the most common type used in circuits.

Variable Resistors: Also known as potentiometers or rheostats, these resistors allow for adjustable resistance, making them useful for applications like volume controls and tuning circuits.

Specialty Resistors: This category includes thermistors (temperature-sensitive resistors), photoresistors (light-sensitive resistors), and others designed for specific functions.

B. Key Specifications of Resistors

When selecting resistors for a circuit, several key specifications must be considered:

1. Resistance Value

The resistance value is the primary specification of a resistor, determining how much it will resist the flow of current. It is typically marked on the resistor body using a color code or printed value.

2. Tolerance

Tolerance indicates the precision of the resistor's resistance value. It is expressed as a percentage and represents the allowable deviation from the nominal value. For example, a resistor with a 5% tolerance could have a resistance value that is 5% higher or lower than its stated value.

3. Power Rating

The power rating of a resistor indicates the maximum amount of power it can dissipate without overheating. It is measured in watts (W) and is crucial for ensuring that the resistor operates safely within its limits.

4. Temperature Coefficient

The temperature coefficient describes how the resistance value changes with temperature. It is expressed in parts per million per degree Celsius (ppm/°C) and is important for applications where temperature variations are expected.

III. Importance of Product Standards

A. Ensuring Quality and Reliability

Product standards for resistors are essential for ensuring that these components meet specific quality and reliability criteria. Adhering to established standards helps manufacturers produce resistors that perform consistently and reliably in various applications.

B. Facilitating Compatibility and Interoperability

In a world where electronic devices are increasingly interconnected, compatibility and interoperability are critical. Product standards ensure that resistors can be used interchangeably in different circuits and devices, reducing the risk of failure and enhancing overall system performance.

C. Enhancing Safety in Electronic Applications

Safety is paramount in electronic applications, especially in critical systems such as medical devices, automotive electronics, and industrial machinery. Product standards help mitigate risks associated with resistor failure, ensuring that devices operate safely and effectively.

D. Supporting Global Trade and Market Access

In an increasingly globalized market, adherence to international product standards facilitates trade and market access. Manufacturers that comply with recognized standards can more easily enter new markets and gain the trust of customers and regulatory bodies.

IV. Key Product Standards for Resistors

A. International Electrotechnical Commission (IEC) Standards

The IEC is a leading organization that develops international standards for electrical and electronic devices. Several IEC standards are relevant to resistors, ensuring their quality and performance.

1. Overview of IEC Standards Relevant to Resistors

IEC standards cover various aspects of resistor design, testing, and performance. These standards provide guidelines for manufacturers to ensure that their products meet international quality benchmarks.

2. Specific IEC Standards (e.g., IEC 60115)

One of the key IEC standards for resistors is IEC 60115, which outlines the general requirements for fixed resistors. This standard specifies testing methods, performance characteristics, and quality assurance measures to ensure that resistors meet the necessary criteria for reliability and safety.

B. American National Standards Institute (ANSI) Standards

The ANSI is another important organization that develops standards for various industries, including electronics. ANSI standards for resistors focus on performance, testing, and safety.

1. Overview of ANSI Standards Relevant to Resistors

ANSI standards provide guidelines for the design and testing of resistors, ensuring that they meet specific performance criteria. These standards are often referenced by manufacturers and engineers in the United States.

2. Specific ANSI Standards (e.g., ANSI/IEEE Standards)

One notable ANSI standard is the ANSI/IEEE 1149.1 standard, which addresses the testing of digital circuits, including those that utilize resistors. This standard helps ensure that resistors function correctly within digital systems.

C. Joint Electron Device Engineering Council (JEDEC) Standards

JEDEC is an organization that develops standards for the semiconductor industry, including standards related to resistors.

1. Overview of JEDEC Standards Relevant to Resistors

JEDEC standards focus on the performance and reliability of electronic components, including resistors. These standards help ensure that resistors meet the necessary criteria for use in semiconductor applications.

2. Specific JEDEC Standards

JEDEC standards such as JESD22-A114 outline the testing methods for resistors used in semiconductor devices, ensuring that they can withstand the stresses of modern electronic applications.

D. Other Relevant Standards Organizations

In addition to IEC, ANSI, and JEDEC, several other organizations develop standards relevant to resistors.

1. Underwriters Laboratories (UL)

UL is a global safety certification organization that develops standards for various products, including electronic components. UL standards for resistors focus on safety and performance, ensuring that these components can be used safely in various applications.

2. European Committee for Electrotechnical Standardization (CENELEC)

CENELEC develops European standards for electrical and electronic products, including resistors. These standards ensure that resistors meet specific performance and safety criteria for use in European markets.

V. Testing and Certification Processes

A. Overview of Testing Methods for Resistors

To ensure compliance with product standards, resistors undergo various testing methods.

1. Electrical Testing

Electrical testing involves measuring the resistance value, tolerance, and power rating of resistors. This testing ensures that resistors meet the specified performance criteria and function correctly in circuits.

2. Environmental Testing

Environmental testing assesses how resistors perform under different environmental conditions, such as temperature, humidity, and mechanical stress. This testing is crucial for ensuring that resistors can withstand the conditions they will encounter in real-world applications.

B. Certification Processes for Compliance with Standards

1. Role of Third-Party Testing Labs

Third-party testing labs play a vital role in the certification process. These independent organizations conduct rigorous testing to verify that resistors comply with relevant standards. Their certification provides assurance to manufacturers and customers that the products meet the necessary quality and safety criteria.

2. Importance of Documentation and Traceability

Documentation and traceability are essential components of the certification process. Manufacturers must maintain detailed records of testing procedures, results, and compliance with standards. This documentation is crucial for demonstrating compliance to regulatory bodies and customers.

VI. Challenges in Compliance with Product Standards

A. Variability in Manufacturing Processes

One of the significant challenges in compliance with product standards is the variability in manufacturing processes. Differences in materials, equipment, and techniques can lead to inconsistencies in resistor performance, making it challenging to meet established standards.

B. Evolving Technology and Standards

As technology advances, product standards must also evolve to keep pace with new developments. This can create challenges for manufacturers who must adapt their processes and products to comply with updated standards.

C. Globalization and Differing Regional Standards

In a globalized market, manufacturers often face the challenge of navigating differing regional standards. Compliance with multiple standards can be complex and costly, requiring manufacturers to invest in additional testing and certification processes.

VII. Future Trends in Resistor Standards

A. Impact of Emerging Technologies (e.g., IoT, AI)

Emerging technologies such as the Internet of Things (IoT) and artificial intelligence (AI) are driving changes in the electronics industry. As these technologies become more prevalent, resistor standards will need to adapt to address new performance and reliability requirements.

B. Sustainability and Environmental Considerations

Sustainability is becoming an increasingly important consideration in the electronics industry. Future resistor standards may incorporate environmental criteria, encouraging manufacturers to adopt more sustainable practices and materials.

C. Potential Changes in Regulatory Frameworks

As regulatory frameworks evolve, manufacturers may face new compliance requirements. Staying informed about potential changes in regulations and standards will be crucial for manufacturers to ensure ongoing compliance.

VIII. Conclusion

In conclusion, product standards for resistors are essential for ensuring quality, reliability, and safety in electronic applications. These standards facilitate compatibility and interoperability, support global trade, and enhance the overall performance of electronic devices. As technology continues to evolve, manufacturers and engineers must prioritize adherence to these standards to meet the demands of the modern electronics landscape.

The future of resistor standards will likely be shaped by emerging technologies, sustainability considerations, and evolving regulatory frameworks. By staying informed and proactive, manufacturers can navigate the challenges of compliance and contribute to the development of high-quality, reliable electronic components.

IX. References

1. International Electrotechnical Commission (IEC). (n.d.). IEC 60115: Fixed Resistors.

2. American National Standards Institute (ANSI). (n.d.). ANSI/IEEE 1149.1: Standard Test Access Port and Boundary-Scan Architecture.

3. Joint Electron Device Engineering Council (JEDEC). (n.d.). JESD22-A114: Reliability Testing of Resistors.

4. Underwriters Laboratories (UL). (n.d.). UL Standards for Safety.

5. European Committee for Electrotechnical Standardization (CENELEC). (n.d.). CENELEC Standards for Electrical Components.

This blog post provides a comprehensive overview of the product standards for resistors, emphasizing their importance and the implications for manufacturers and engineers in the electronics industry. By understanding these standards, stakeholders can ensure the quality and reliability of their products, ultimately contributing to the advancement of technology and safety in electronic applications.