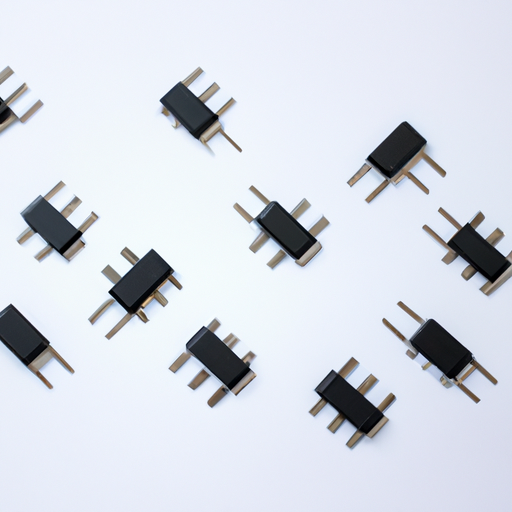

Chip resistors are essential components in electronic circuits, providing precise resistance values to control the flow of current. These small, rectangular devices are widely used in a variety of applications, from consumer electronics to industrial machinery. In this article, we will explore the key features of chip resistors and how they contribute to the performance and reliability of electronic systems.

One of the most distinctive features of chip resistors is their compact size and rectangular shape. These devices are typically made of a ceramic substrate with a thin film of resistive material deposited on top. The small size of chip resistors allows for high-density mounting on circuit boards, saving valuable space in electronic devices. The rectangular shape also makes them easy to handle and install, with standardized dimensions for compatibility with automated assembly equipment.

2. Resistance Value

Chip resistors are available in a wide range of resistance values, from fractions of an ohm to several megaohms. The resistance value is determined by the thickness and length of the resistive film, as well as the material used. Common materials for chip resistors include carbon, metal, and metal oxide, each with its own characteristics in terms of stability, temperature coefficient, and power handling capability. The resistance value is typically marked on the body of the chip resistor using a color code or alphanumeric code for easy identification.

3. Tolerance

The tolerance of a chip resistor refers to the allowable deviation from the specified resistance value. Tolerance is expressed as a percentage, with common values ranging from 1% to 10%. For example, a chip resistor with a resistance value of 1 kilohm and a tolerance of 5% may have an actual resistance between 950 ohms and 1050 ohms. Tighter tolerance values are available for precision applications, but they typically come at a higher cost. It is important to select chip resistors with the appropriate tolerance to ensure the accuracy and reliability of the circuit.

4. Power Rating

The power rating of a chip resistor indicates the maximum amount of power it can dissipate without overheating. Power rating is determined by the size of the resistor and the material used, with higher power ratings requiring larger resistors or materials with better heat dissipation properties. Common power ratings for chip resistors range from 1/16 watt to several watts, depending on the size and construction of the device. It is important to select chip resistors with a power rating that exceeds the expected power dissipation in the circuit to prevent damage or failure.

5. Temperature Coefficient

The temperature coefficient of a chip resistor describes how its resistance changes with temperature. This property is important for applications where the operating temperature can vary significantly, such as automotive or industrial environments. Chip resistors are available with different temperature coefficients, typically expressed in parts per million per degree Celsius (ppm/°C). Common temperature coefficients include 100 ppm/°C for general-purpose applications and 25 ppm/°C for precision applications. Choosing chip resistors with a low temperature coefficient helps maintain the stability and accuracy of the circuit over a wide temperature range.

6. Reliability

Reliability is a critical feature of chip resistors, especially in mission-critical applications where downtime or failure can have serious consequences. Chip resistors are designed to withstand mechanical stress, thermal cycling, and environmental factors such as humidity and vibration. The materials used in chip resistors are selected for their stability and durability, ensuring long-term performance in harsh conditions. Manufacturers conduct rigorous testing and quality control measures to ensure the reliability of chip resistors, with certifications such as ISO 9001 and RoHS compliance indicating adherence to industry standards.

7. Packaging

Chip resistors are typically packaged in reels or tape and reel for automated assembly, with standard sizes and configurations for compatibility with pick-and-place machines. The packaging of chip resistors also includes markings for identification, such as the resistance value, tolerance, and manufacturer's logo. Some chip resistors are available in surface-mount or through-hole configurations, depending on the requirements of the circuit design. Packaging options for chip resistors may also include special coatings or materials for enhanced protection against moisture, dust, or corrosive environments.

8. Cost

Cost is an important consideration when selecting chip resistors for a circuit design, as it can impact the overall bill of materials and production costs. The price of chip resistors depends on factors such as resistance value, tolerance, power rating, and packaging options. Higher precision, tighter tolerance, and specialized materials may increase the cost of chip resistors, while standard values and configurations are more affordable. It is important to balance the performance requirements of the circuit with the budget constraints to choose chip resistors that offer the best value for the application.

In conclusion, chip resistors are essential components in electronic circuits, providing precise resistance values to control current flow and ensure the performance and reliability of electronic systems. With their compact size, wide range of resistance values, and high reliability, chip resistors are versatile components that find applications in a variety of industries. By understanding the key features of chip resistors, engineers and designers can select the right components for their circuits and achieve optimal performance and efficiency.