What are the Manufacturing Processes of the Latest Capacitor Manufacturers?

I. Introduction

Capacitors are essential components in modern electronics, serving as energy storage devices that can release energy quickly when needed. They play a crucial role in various applications, from power supply circuits to signal processing in communication devices. As the demand for smaller, more efficient electronic devices continues to rise, the capacitor manufacturing industry has evolved significantly, adopting advanced technologies and innovative materials to meet these challenges. This blog post explores the manufacturing processes of the latest capacitor manufacturers, highlighting the types of capacitors, the manufacturing process, innovations, challenges, and future trends in the industry.

II. Types of Capacitors

Capacitors come in various types, each suited for specific applications:

A. Ceramic Capacitors

Ceramic capacitors are widely used due to their small size and high capacitance values. They are made from ceramic materials and are often used in high-frequency applications.

B. Electrolytic Capacitors

Electrolytic capacitors are polarized components that offer high capacitance values. They are commonly used in power supply circuits and audio applications.

C. Film Capacitors

Film capacitors are made from thin plastic films and are known for their stability and reliability. They are often used in applications requiring high precision.

D. Tantalum Capacitors

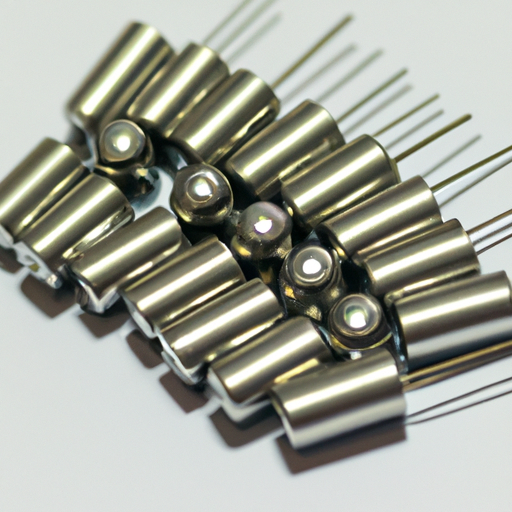

Tantalum capacitors are known for their high capacitance and small size. They are often used in military and aerospace applications due to their reliability.

E. Supercapacitors

Supercapacitors, or ultracapacitors, offer high energy density and are used in applications requiring rapid charge and discharge cycles, such as in electric vehicles.

F. Comparison of Different Types and Their Applications

Each type of capacitor has its unique characteristics, making them suitable for different applications. For instance, ceramic capacitors are ideal for high-frequency circuits, while electrolytic capacitors are preferred in power supply applications due to their high capacitance.

III. Overview of the Manufacturing Process

The manufacturing process of capacitors involves several key steps:

A. Raw Material Selection

The selection of raw materials is critical in capacitor manufacturing. Manufacturers use various materials, including ceramics, aluminum, tantalum, and polymers, depending on the type of capacitor being produced. Quality control measures are implemented to ensure that the materials meet industry standards and specifications.

B. Design and Engineering

The design phase involves using Computer-Aided Design (CAD) software to create detailed models of the capacitors. Prototyping and testing are essential to validate the designs before moving to mass production.

C. Production Techniques

1. **Thin-Film Deposition**: This technique involves depositing thin layers of materials onto a substrate to create the capacitor's dielectric layer.

2. **Dielectric Layer Formation**: The dielectric layer is crucial for the capacitor's performance, and various methods, such as chemical vapor deposition, are used to form it.

3. **Electrode Fabrication**: Electrodes are fabricated using techniques like sputtering or etching, which define the capacitor's electrical characteristics.

4. **Assembly Processes**: The final assembly involves integrating the dielectric and electrodes into a complete capacitor unit, followed by encapsulation to protect the components.

D. Quality Assurance

Quality assurance is vital in capacitor manufacturing. Testing methods, including electrical testing and environmental stress testing, ensure that the capacitors meet performance standards and comply with industry regulations.

IV. Innovations in Capacitor Manufacturing

The capacitor manufacturing industry is witnessing several innovations that enhance performance and sustainability:

A. Advanced Materials

1. **Nanotechnology in Capacitors**: The use of nanomaterials can improve the performance of capacitors by increasing capacitance and reducing size.

2. **Biodegradable Materials**: Some manufacturers are exploring biodegradable materials to reduce environmental impact, aligning with global sustainability goals.

B. Automation and Robotics

Automation and robotics are transforming capacitor manufacturing by increasing efficiency and precision. Manufacturers are implementing automated assembly lines and robotic systems to streamline production processes. Case studies of leading manufacturers show significant improvements in output and quality control through automation.

C. Sustainable Practices

Sustainability is becoming a priority in capacitor manufacturing. Companies are adopting energy-efficient manufacturing processes and implementing waste reduction strategies to minimize their environmental footprint.

V. Case Studies of Leading Capacitor Manufacturers

A. Manufacturer A: Overview and Processes

Manufacturer A is known for its innovative approach to capacitor design and production. They utilize advanced materials and automated processes to produce high-performance capacitors for various applications.

B. Manufacturer B: Innovations and Technologies

Manufacturer B has made significant strides in using nanotechnology to enhance capacitor performance. Their research and development efforts focus on creating smaller, more efficient capacitors that meet the demands of modern electronics.

C. Manufacturer C: Sustainability Initiatives

Manufacturer C has implemented several sustainability initiatives, including energy-efficient manufacturing processes and the use of biodegradable materials. Their commitment to sustainability has positioned them as a leader in the industry.

D. Comparative Analysis of Manufacturing Processes

A comparative analysis of these manufacturers reveals that while each has its unique strengths, common trends include the adoption of automation, advanced materials, and a focus on sustainability.

VI. Challenges in Capacitor Manufacturing

Despite the advancements in capacitor manufacturing, several challenges persist:

A. Supply Chain Issues

The global supply chain for raw materials can be volatile, affecting production schedules and costs.

B. Technological Limitations

While technology is advancing, some manufacturers face limitations in scaling up new technologies for mass production.

C. Environmental Regulations

Increasingly stringent environmental regulations require manufacturers to adapt their processes, which can be costly and time-consuming.

D. Market Competition

The capacitor market is highly competitive, with numerous players vying for market share. Manufacturers must continuously innovate to stay ahead.

VII. Future Trends in Capacitor Manufacturing

The future of capacitor manufacturing is promising, with several emerging trends:

A. Emerging Technologies

Technologies such as 3D printing and advanced materials are expected to revolutionize capacitor design and production.

B. Market Predictions

The demand for capacitors is projected to grow, driven by advancements in consumer electronics, electric vehicles, and renewable energy systems.

C. Potential for Growth in Specific Sectors

Sectors such as electric vehicles and renewable energy are expected to see significant growth, creating new opportunities for capacitor manufacturers.

VIII. Conclusion

In summary, the manufacturing processes of the latest capacitor manufacturers are characterized by advanced materials, innovative production techniques, and a commitment to sustainability. As the demand for capacitors continues to rise, manufacturers must embrace continuous innovation to meet the evolving needs of the electronics industry. The future of capacitor manufacturing looks bright, with emerging technologies and growing markets poised to drive further advancements in this critical sector.

IX. References

- Academic journals on capacitor technology and manufacturing processes.

- Industry reports detailing market trends and forecasts.

- Manufacturer websites and publications providing insights into their processes and innovations.

This comprehensive overview of capacitor manufacturing processes highlights the industry's dynamic nature and the importance of innovation in meeting the demands of modern electronics.